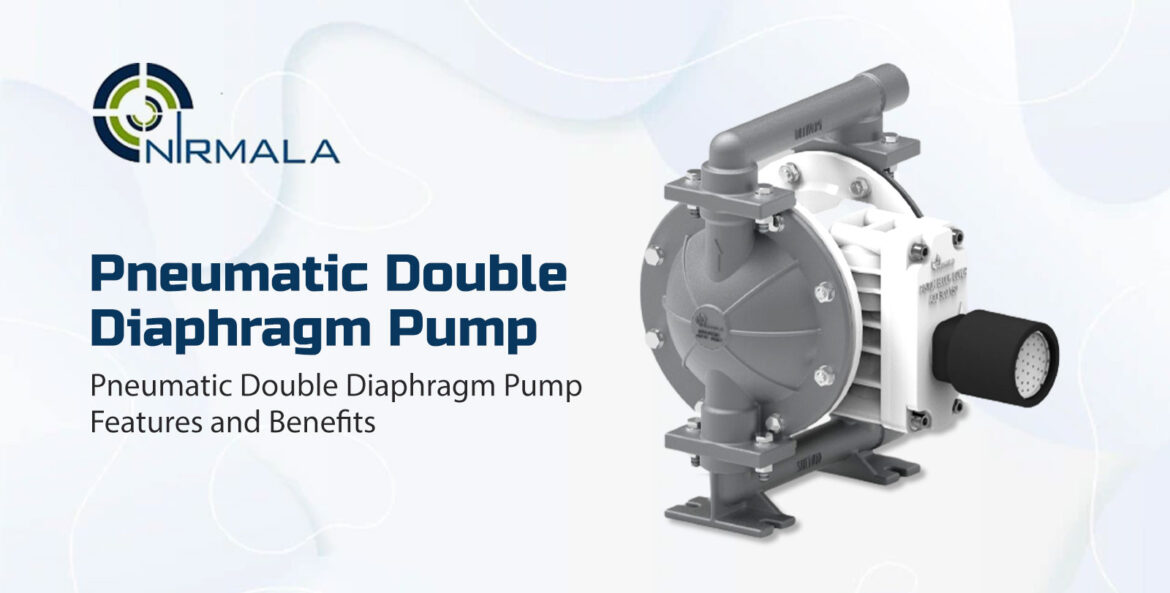

In the world of fluid handling, the pneumatic double diaphragm pump stands as a versatile and efficient solution, offering a myriad of features and benefits that cater to diverse industrial applications. From its robust design to its unparalleled functionality, this pumping marvel has earned its place as a reliable workhorse across various industries. Let’s delve into the key features and benefits that make the pneumatic double diaphragm pump a powerhouse in fluid transfer and management.

Benefits and Features of Pneumatic Double Diaphragm Pump

Dual Diaphragm Design

At the core of the pneumatic double diaphragm pump’s efficiency is its ingenious dual-diaphragm design. This unique feature not only ensures a consistent and reliable flow but also provides a failsafe mechanism. Should one diaphragm experience wear or damage, the other can seamlessly take over, preventing costly downtime and potential hazards. This redundancy makes the pump a dependable choice for critical applications where continuous operation is paramount.

Versatility Across Fluids

One of the standout features of these pumps is their ability to handle a wide spectrum of fluids, from thin solvents to thick slurries. Whether transferring abrasive chemicals or delicate fluids, its gentle pumping action minimizes shear forces, preserving the integrity of shear-sensitive materials. This versatility makes it an ideal choice for industries ranging from chemical processing and paint manufacturing to pharmaceuticals.

Self-Priming Capability

The pneumatic double diaphragm pump’s self-priming capability is a game-changer in applications where maintaining a continuous flow is crucial. This feature allows the pump to evacuate air from the suction line, ensuring quick and efficient startup without the need for external priming. In situations where time is of the essence, this capability significantly contributes to enhanced operational efficiency.

Minimal Maintenance Requirements

In the realm of industrial equipment, downtime is the adversary of productivity. Pneumatic Pumps boast a simplistic and rugged design that translates to minimal maintenance requirements. The absence of intricate components and the pump’s ability to handle challenging fluids contribute to extended service intervals, reducing the overall cost of ownership and enhancing the pump’s reliability.

ATEX Compliance

Safety is paramount in industries dealing with volatile or hazardous materials. Many pneumatic double diaphragm pumps are designed to comply with ATEX (ATmospheres EXplosibles) directives, ensuring their suitability for use in potentially explosive atmospheres. This compliance provides peace of mind to operators working in environments where safety standards are non-negotiable.

Portable and Compact

In a world where flexibility is key, the pneumatic double diaphragm pump stands tall. Its portable and compact design makes it adaptable to various settings, whether mounted on a skid for stationary applications or utilized in mobile setups. This flexibility extends its reach to industries such as construction, mining, and agriculture, where on-the-go fluid transfer is a common requirement.

Conclusion

As industries continue to evolve, the demand for reliable, efficient, and versatile fluid-handling solutions has never been higher. The pneumatic double diaphragm pump, with its innovative features and multifaceted benefits, emerges as a cornerstone in this landscape. From safeguarding against unexpected downtimes to navigating hazardous environments with ease, this pumping marvel proves its mettle across the spectrum of industrial applications, making it a worthy investment for those seeking precision and power in fluid management.

Nirmala Pumps & Equipments

Nirmala Pumps & Equipments is an Indian company that manufactures and supplies pump systems, valves, strainers, and pneumatic pumps since 1989. We provide services to different industries, both domestically and internationally, such as citrus, distilling, wastewater treatment, and petroleum.