Nirmala Pumps & Equipments established in 1989

Polypropylene is the most widely used material for chemical- technical applications. Compared to PE, it displays greater rigidly particularly in the upper service temperature range (up to + 100 ° C). Its key characteristics also include excellent chemical resistance, good long term properties when exposed to various substances and high stress crack resistance.

There are two types of polypropylene: Homo polymers (PP-H) and copolymers (PP-C). PP-H consists entirely of a combination of propylene monomers and covers a service temperature range 0 °C to +100° C, PP-C features a chemical combination of propylene monomers and ethylene monomers, which increases the material’s impact strength at low temperature. PP-C covers a service temperature range from -20 °C to +80 °C and is less rigid from than PP-H.

DATA SHEET FOR PPH Pipe

- Considerable reduction in pressure loss due to improved hydraulic properties.

- Significantly lower risk of particle deposits and bacteria due to ultra-smooth surfaces.

- Potential cost-savings as a result of extended intervals between cleaning.

- Many different potential uses due to a service temperature range from 0° C to + 100 °C, depending on the application.

- Safe installation and assembly of pipe due to improved impact strength, even at low temperatures up to 0°

- Longer service life due to enhanced chemical resistance and minimized risk of stress cracks.

- Greater safety margin due to improved weld quality.

- Higher degree of safety when welding pipes in locations that are difficult to access.

- Acid fillings stations

- Effluent Treatment/Disposal Plant

- Laboratories

- Refineries

- Automotive Industry

- Electroplating Plants

- Nuclear Research Centers

- Textile Mills

- Chemical Industry

- Food and Beverage

- Paper & pulp mills

- Thermal baths

- Construction (Plumbing)

- Galvanizing Plants

- Pharmaceuticals Industry

- Desalination plants

- Pickling lines

- Suction and Exhaust pipelines

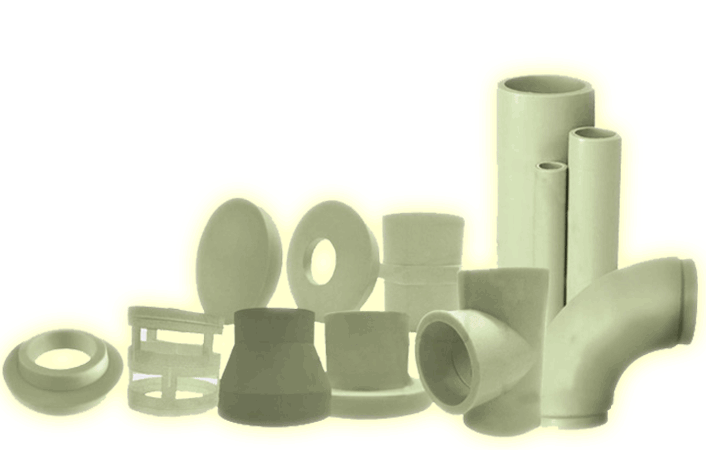

- Lined piping ( Mild Steel + PPH / PVDF)

- Water, Effluent, Chemical Transport

- Storage tank for chemicals

- Hoods, fume ducts

| SIZE | PRESSURE RATING | |||||

| 2.5 kg/cm2 | 4 kg/cm2 | 6 kg/cm2 | 10 kg/cm2 | 16 kg/cm2 | ||

| INCH | OD(MM) | THICKNESS(mm) | ||||

| ½” | 20 | 2.5 | 2.8 | |||

| ¾” | 25 | 2.7 | 3.5 | |||

| 1” | 32 | 3.0 | 4.5 | |||

| 1 ¼” | 40 | 3.7 | 5.8 | |||

| 1 ½” | 50 | 2.9 | 4.6 | 6.9 | ||

| 2” | 63 | 3.6 | 5.8 | 8.7 | ||

| 2 ½” | 75 | 4.3 | 6.9 | 10.4 | ||

| 3” | 90 | 3.5 | 5.1 | 8.2 | 12.5 | |

| 4” | 110 | 4.3 | 6.3 | 10.0 | 15.2 | |

| 6” | 160 | 3.9 | 6.2 | 9.1 | 14.6 | 22.1 |

| Moulding compound extruded | PP-H,ECH,16-09-003 |

| Extruded to moulding compound standard | DIN EN ISO 19069-1 |

| Moulding compound pressed | PP-H,QCH,16-09-003 |

| Pressed to moulding compound standard | DIN EN ISO 19069-1 |

| Density, g/cm³,

DIN EN ISO 1183 |

0.910 |

| Tensile modulus of elasticity, MPa, DIN EN ISO 527 | 1700 |

| Yield stress, MPa, DIN EN ISO 527 | 33 |

| Elongation at yield, % , DIN EN ISO 527 | 8 |

| Impact strength, kJ/m², DIN EN ISO 179 | without break |

| Notched impact strength Charpy, kJ/m², DIN EN ISO 179-1eA | 9 |

| Shore hardness D (15 s), DIN EN ISO 868 | 72 |

| Mean coefficient of linear thermal expansion, K-1

, ISO 11359-2 |

1,6 x 10-4 |

| Surface resistivity, Ohm , DIN IEC 60093 | ≥ 1013 |

| Temperature range, °C | 0 to +100 |

| Fire behaviour DIN 4102 | DIN 4102 B2 normal flammability (self-assessment without test certificate) |

| Food compliance EU 10/2011 | yes |

| Food compliance FDA | yes |