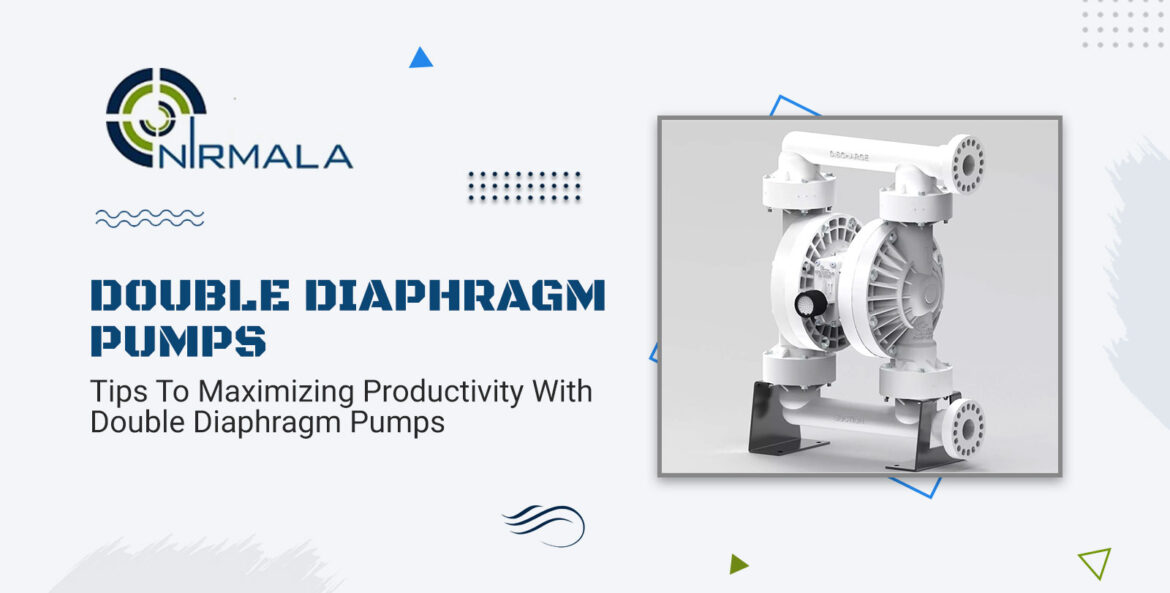

Double Diaphragm Pumps are widely used in various industries, such as chemical, food and beverage, and pharmaceuticals, due to their ability to handle a wide range of liquids, from thin and light to thick and dense. However, to achieve the best results and maximize productivity, it’s crucial to know the right tips for using double pumps.

Proper Selection of Pump Type and Size:

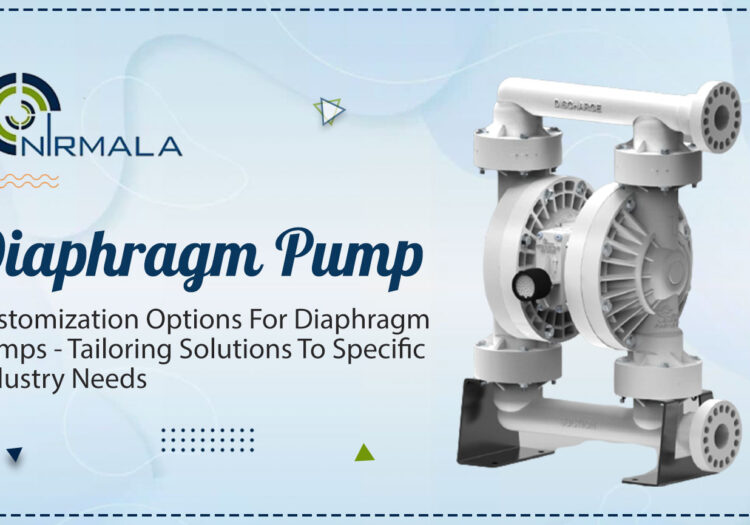

Choosing the right type and size of pump is crucial for maximizing productivity. Factors such as the fluid’s viscosity, temperature, and chemical compatibility should be considered when selecting the type and size of the pump. For example, pumps offered by Double Diaphragm Pump Suppliers in India are available in various sizes and materials, such as aluminum, stainless steel, and polypropylene. Selecting the appropriate pump size will help ensure that the pump operates at maximum efficiency.

Ensure Optimal Air Pressure:

Diaphragm Pumps operate using compressed air, which is used to push and pull the diaphragms to transfer fluid. One of the most important tips for maximizing productivity with double pumps is to ensure optimal air pressure. The optimal pressure range will depend on the size and material of the pump. It is important to note that using too much air pressure can result in increased wear and tear of the pump while using too little can cause a reduction in flow rate. Optimal air pressure can be achieved by consulting the manufacturer’s manual or testing different air pressure settings until the desired results are achieved.

Proper Installation:

Proper installation of the double pump is vital for its optimal performance. The pump should be installed on a level surface and free of obstructions. The inlet and outlet hoses should be properly connected and free of any kinks or twists that could restrict fluid flow. Additionally, it’s essential to ensure that the air supply is properly connected and adjusted to the optimal pressure range.

Regular Maintenance:

Regular maintenance is necessary to maximize productivity and ensure that the double pump operates at its peak performance. This includes checking and replacing worn diaphragms, inspecting and cleaning the valves, and lubricating the pump. Regular maintenance also involves ensuring that the air supply is clean and dry and the hoses are free of any debris or clogs that could cause a reduction in flow rate.

Use of Accessories:

The use of accessories such as filters, regulators, and lubricators can help to increase the efficiency of the double pump. Filters help to remove any contaminants from the fluid, while regulators help to maintain optimal air pressure. Lubricators help ensure that the pump’s internal parts are lubricated, reducing wear and tear and extending the pump’s life.

Conclusion:

Double Diaphragm Pumps are essential in many industries due to their versatility and ability to handle a wide range of liquids. However, to maximize productivity and achieve the best results, it’s essential to choose the right type and size of the pump, ensure optimal air pressure, install the pump correctly, and perform regular maintenance. Additionally, using accessories such as filters, regulators, and lubricators can further increase the pump’s efficiency. When it comes to relying on the right Double Diaphragm Pump Manufacturers in India, Nirmala Pumps is indeed the best bet which has the legacy of providing premium products.

Nirmala Pumps & Equipments

Nirmala Pumps & Equipments is an Indian company that manufactures and supplies pump systems, valves, strainers, and pneumatic pumps since 1989. We provide services to different industries, both domestically and internationally, such as citrus, distilling, wastewater treatment, and petroleum.