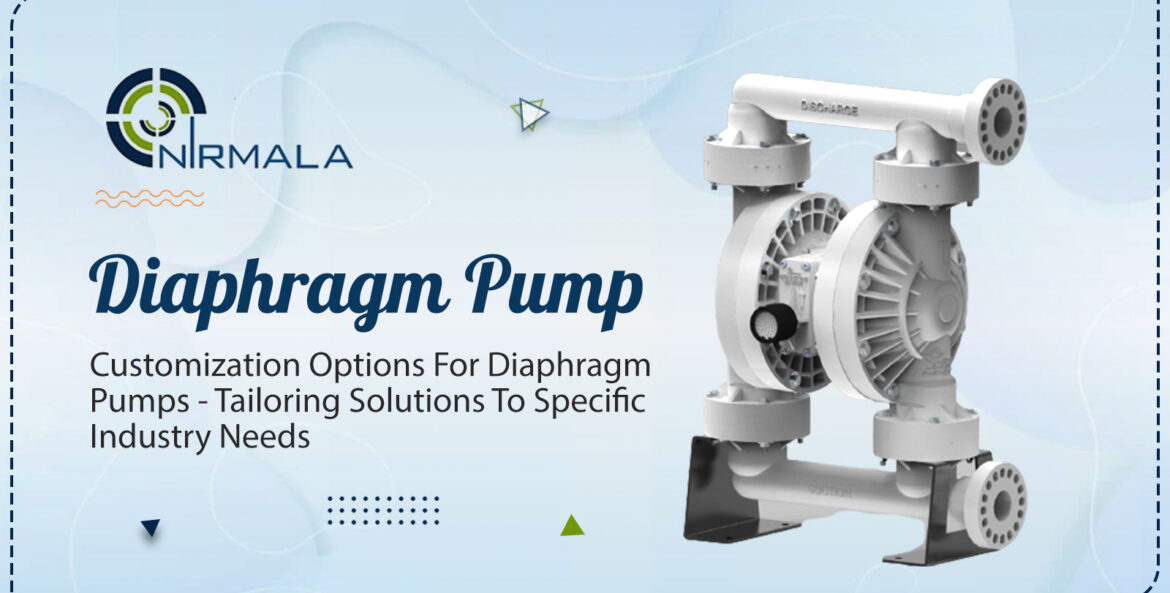

Diaphragm pumps, also known as membrane pumps or AODD (Air-Operated Double Diaphragm) pumps are versatile and reliable fluid handling devices used in various industries for various applications. From chemical processing and food and beverage production to pharmaceutical manufacturing and wastewater treatment, they are designed to handle different fluids, including corrosive and abrasive liquids, dense materials, and slurries.

Materials of Construction

Primary customization options for pumps offered by Diaphragm Pump Manufacturers in India is the choice of construction materials. The pumps can be manufactured from various materials, including metals, plastics, and elastomers, to suit the requirements of different fluids, temperatures, and operating conditions.

For example, in industries such as chemical processing and oil and gas, where aggressive chemicals and corrosive liquids are commonly handled, it can be constructed from materials such as stainless steel, polypropylene, or Hastelloy, which offer high resistance to corrosion and chemical attack. These materials ensure the longevity and durability of the pump, preventing damage from harsh fluids and extending the pump’s service life.

- In industries such as food and beverage, pharmaceuticals, and cosmetics, where hygiene and cleanliness are critical, pumps can be manufactured from FDA-compliant materials such as stainless steel, PTFE (polytetrafluoroethylene) or food-grade elastomers.

- These materials are designed to meet stringent industry standards for cleanliness, ensuring that the pump does not contaminate the fluid being handled and maintaining the integrity of the final product.

Pump Size and Configuration

Pumps are available in various sizes and configurations, allowing customization to suit different flow rates, pressure requirements, and space limitations. The size and configuration of the pump can be selected based on the application’s specific needs, ensuring optimal performance and efficiency.

For applications that require high flow rates and pressure, larger pumps with higher horsepower (HP) and larger fluid passages can be chosen. These pumps are ideal for handling large volumes of fluids and can deliver high performance in demanding applications such as slurry pumping, dewatering, or bulk material transfer.

- Small pumps with lower HP and compact designs can be chosen for applications with lower flow rates and pressure requirements.

- These pumps are suitable for applications where space is limited, such as in OEM (Original Equipment Manufacturer) installations or portable systems, and where energy efficiency is a priority.

Specialized Features

In addition to materials of construction and diaphragm materials, pumps can be customized with specialized features to meet the unique needs of different industries and applications. These specialized features can enhance the pump’s performance, reliability, and efficiency, ensuring optimal operation and productivity.

Some examples of specialized features that can be customized in pumps include:

Explosion-proof motors: For applications in hazardous environments, such as oil refineries or chemical plants, pumps can be equipped with explosion-proof motors that meet industry standards for safety.

Sanitary fittings and connections: In industries such as food and beverage or pharmaceuticals, pumps can be customized with sanitary fittings and connections that meet strict hygiene requirements, ensuring the integrity of the final product.

Leak detection systems: Can be equipped with leak detection systems that monitor for any potential leaks in the pump or diaphragm, providing early warning signs and preventing costly downtime or environmental hazards.

Variable frequency drives (VFDs): VFDs can be integrated into Double Diaphragm Pump for variable speed operation, optimizing the pump’s performance and energy efficiency based on the fluid being handled and the operating conditions.

Remote control and monitoring: The pumps can be customized with remote control and monitoring systems that allow for remote operation, monitoring, and diagnostics, reducing the need for on-site supervision and improving overall efficiency.

Conclusion:

The pumps are highly versatile fluid-handling devices used in various industries for various applications. Customization options for diaphragm pumps allow businesses to tailor the pump system to meet the specific requirements of their industry and application, ensuring optimal performance, reliability, and efficiency. Nirmala Pumps & Equipments is the leading Diaphragm Pump Suppliers in India, and known for its utmost quality.

Nirmala Pumps & Equipments

Nirmala Pumps & Equipments is an Indian company that manufactures and supplies pump systems, valves, strainers, and pneumatic pumps since 1989. We provide services to different industries, both domestically and internationally, such as citrus, distilling, wastewater treatment, and petroleum.