Using compressed air as its power source, the Air Operated Pump is a positive displacement pump. Air pumps are a clean and effective option for product transfer. Viscous products that require minimal or low shear pumping, include solids or are virtually solid are perfect candidates for these pumps (it is a gentle beast). As a product transfer pump, it is widely used in the brewing business, but the mechanism by which it operates and why a brewer would desire one is not always precise.

The Functions Of Air Operated Pump

Air pumps are distinguished from standard electric pumps primarily by using compressed air from an independent air compressor.

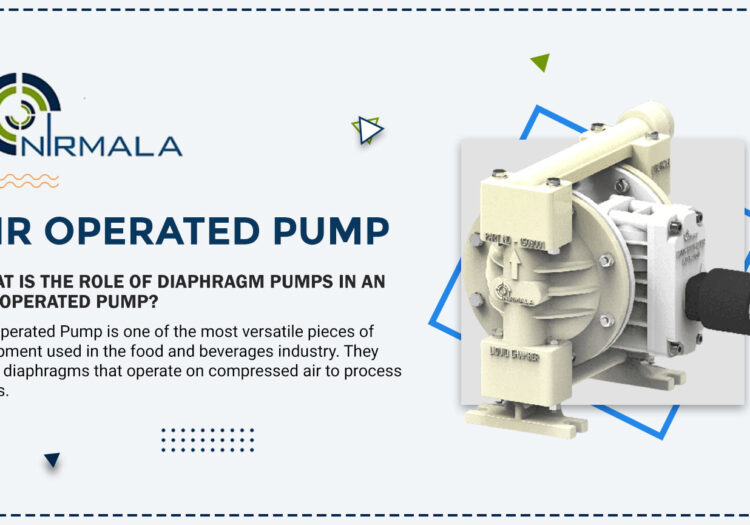

Four check valves/balls, two diaphragms, a central rod assembly, and two air valves make up the pump. One diaphragm will be suctioning fluid while the other discharges it as it moves in and out of the fluid sections. The diaphragm moves out of the liquid section during the suction mode, creating a low-pressure zone that draws fluid into the Pneumatic Double Diaphragm Pump. Discharge mode involves the diaphragm moving back into the fluid section, pushing the product upwards toward the balls/check valves and, finally, the outlet.

It is model-specific regarding how the rod assembly manipulates the air pressure between the diaphragms to cause the latter to slide laterally. Balls inside the check valves open and close the valves in response to the pressure created by the diaphragms. The pressure vacuum created by the diaphragm and balls drives the product through the pump.

How Do You Use An Air Operated Pump?

How can you benefit from a Air Operated Pump that runs on air pressure when it comes to brewing?

- To move and bottle packaged beer.

- Yeast Infusion

- Yeast byproducts from the fermentation tanks

- Transportation of Tank-Cleaning Chemicals in Large Quantities

- Moving beer between barrels and bottles

The air operated is suitable for any product transfer at room temperature or below. Yeast and other waste products can also be transported. You can safely filter your beer through them because they are hygienic. Because the low speeds don’t impart kinetic energy to the product, they’re also perfect for carbonated beverages.

Why the use Air operated Pump?

Pressurized goods (like carbonated beverages) can be transferred at low pressure and speeds using air-operated pumps supplied by Air Operated Pump Suppliers in India. In the case of a bubbly or foamy product, this is of great help. The cleaner is also safe for use on delicate items. Due to the oil-free design of the self-priming pneumatic motor, no lubrication is necessary. Cavitation is avoided, and deadheading is possible without consequence.

A few details about the Air Operated Pump:

- Extremely fine-grained regulation of flow

- Allows for operation at subsonic velocities

- Risks depletion

- CIPable

- The ability to transport items that are primarily solid or which incorporate solids

- Effects of low shear

Conclusion:

Nirmala Pumps and Equipments is the industry leader in producing and providing a wide selection of high-quality air-operated pumps. These robust pumps are helpful in the chemical and pharmaceutical industries for moving around highly flammable solvents and other chemicals like acetone and methylene chloride. It is the best Air Operated Pump Manufacturers in India.

Nirmala Pumps & Equipments

Nirmala Pumps & Equipments is an Indian company that manufactures and supplies pump systems, valves, strainers, and pneumatic pumps since 1989. We provide services to different industries, both domestically and internationally, such as citrus, distilling, wastewater treatment, and petroleum.