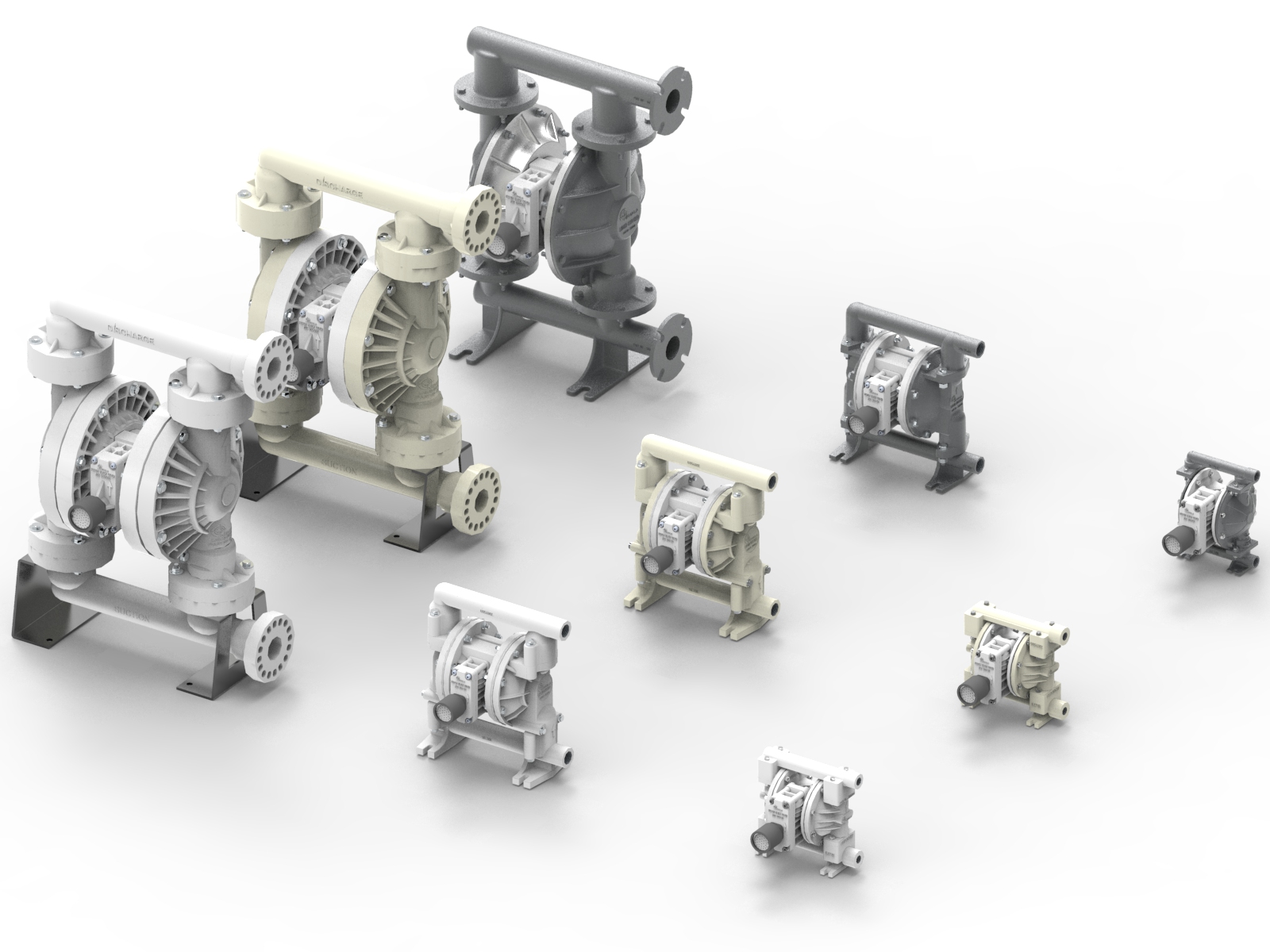

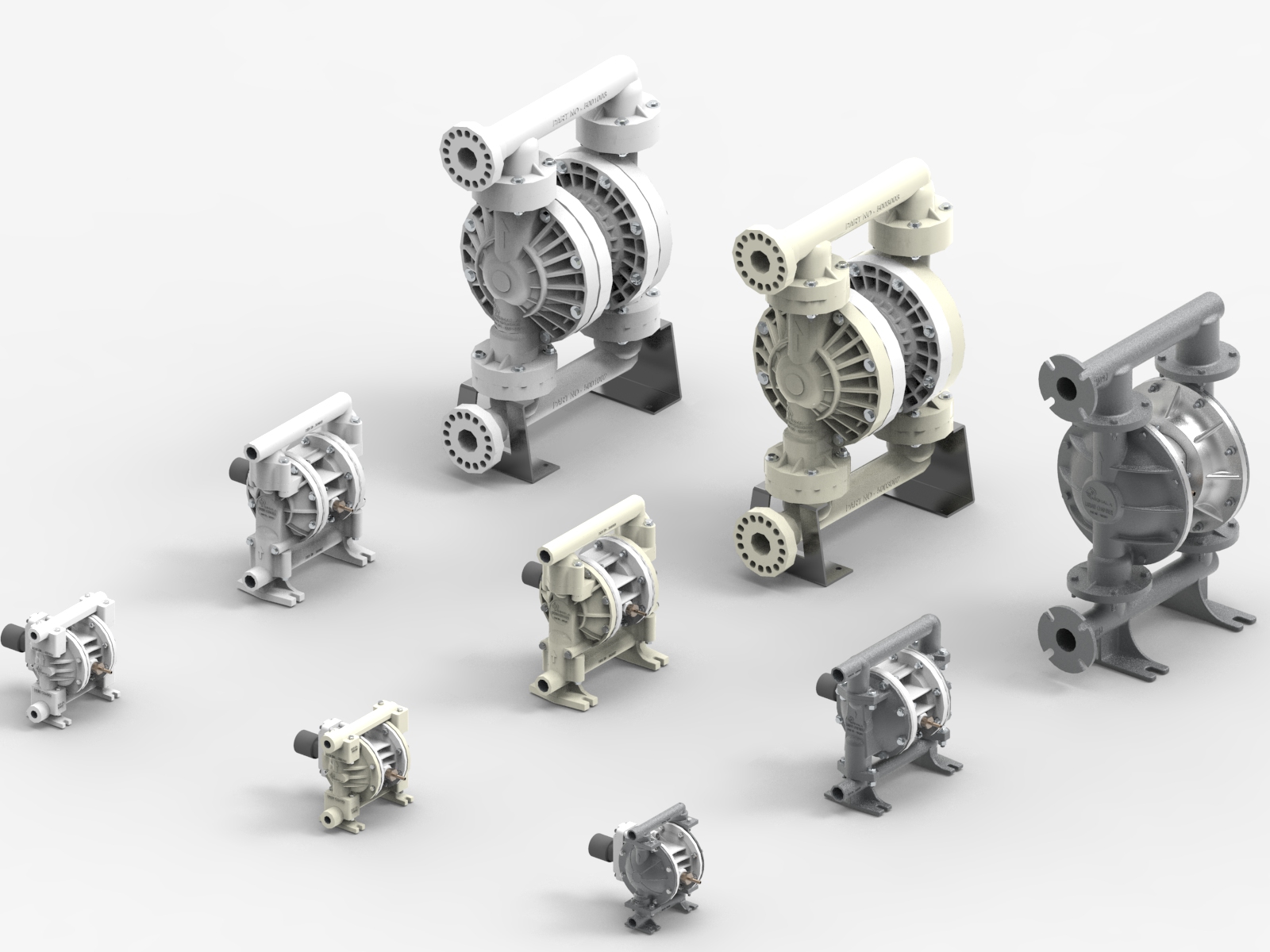

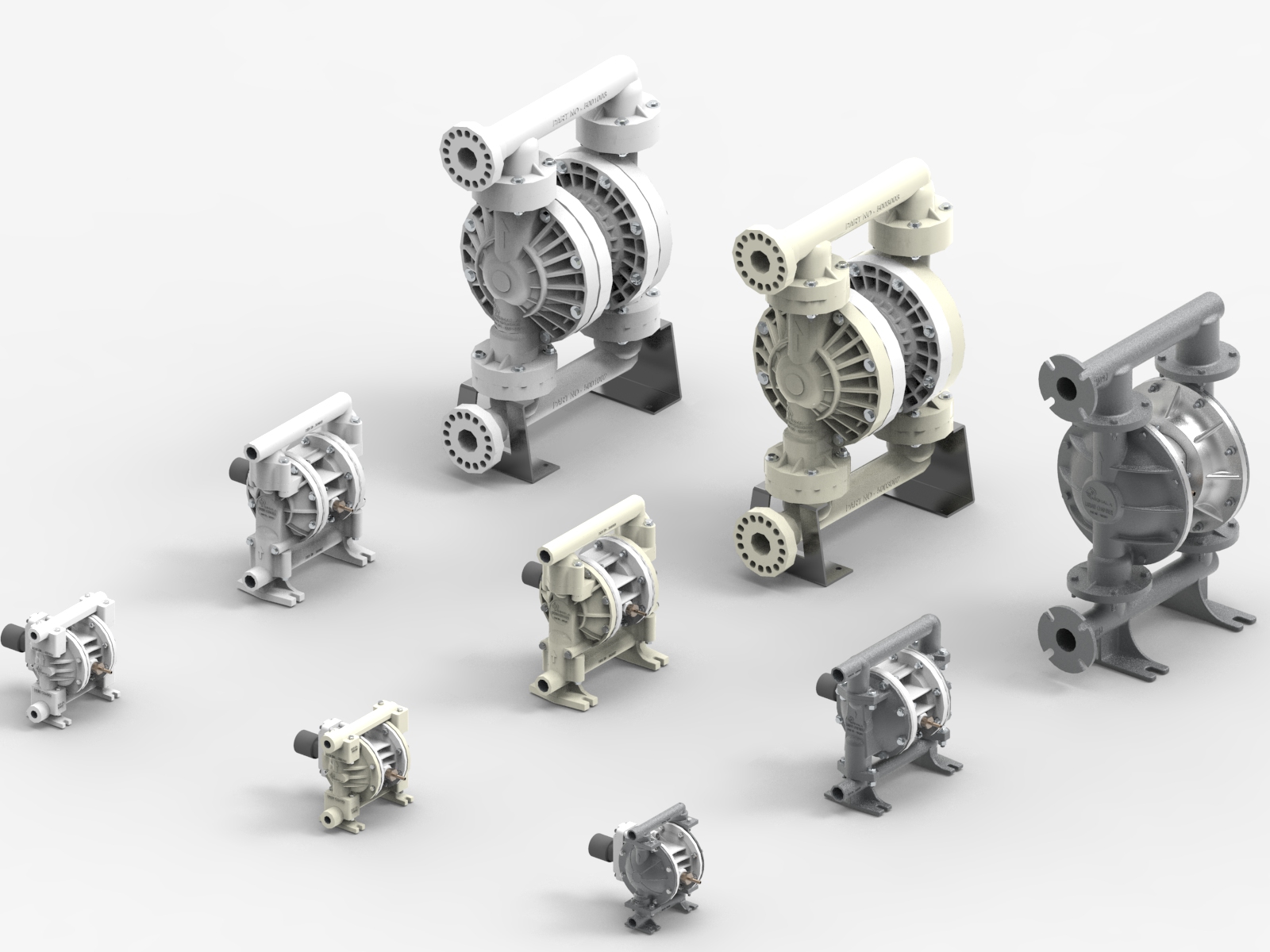

Models

Various Models We Have

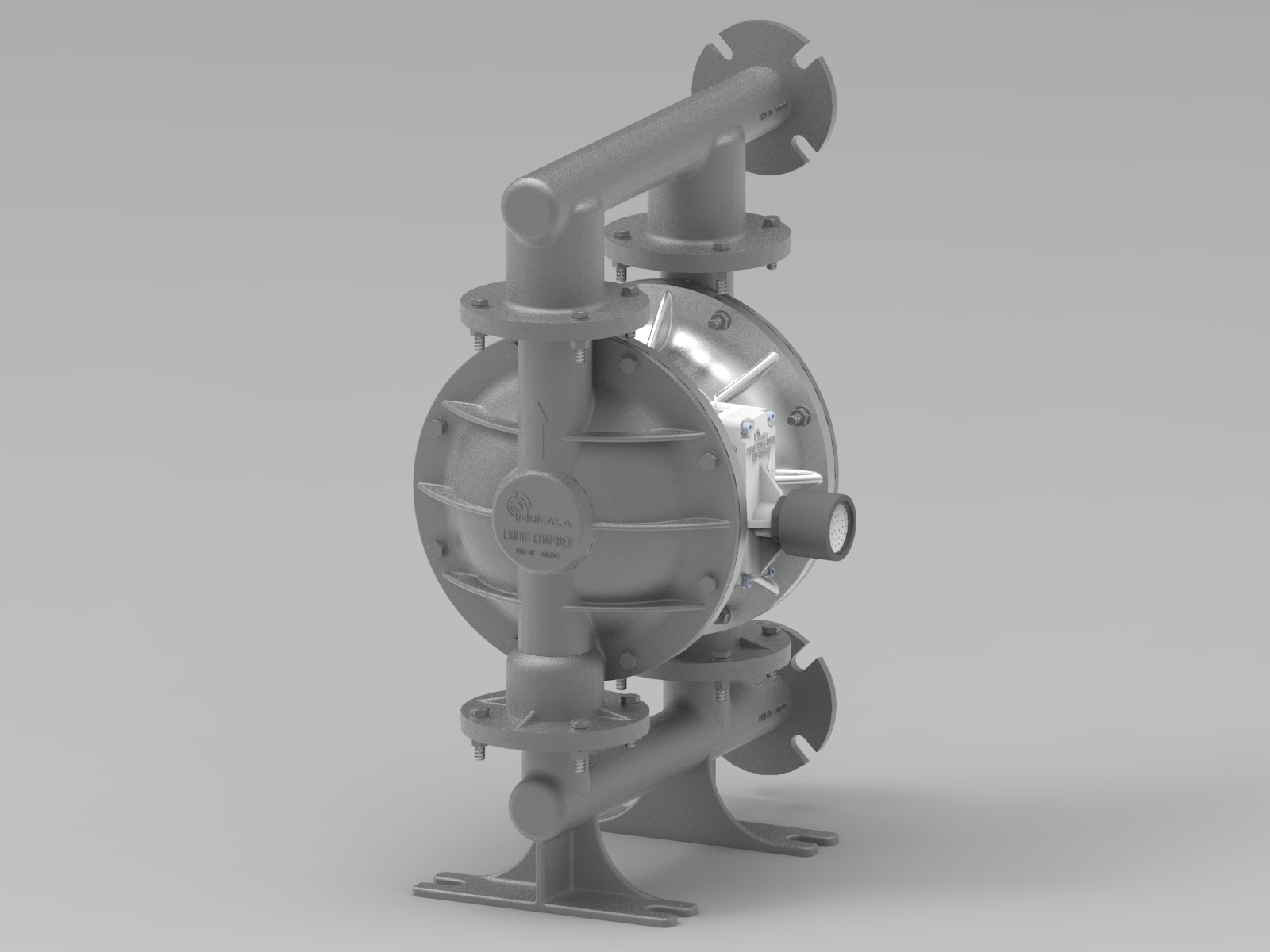

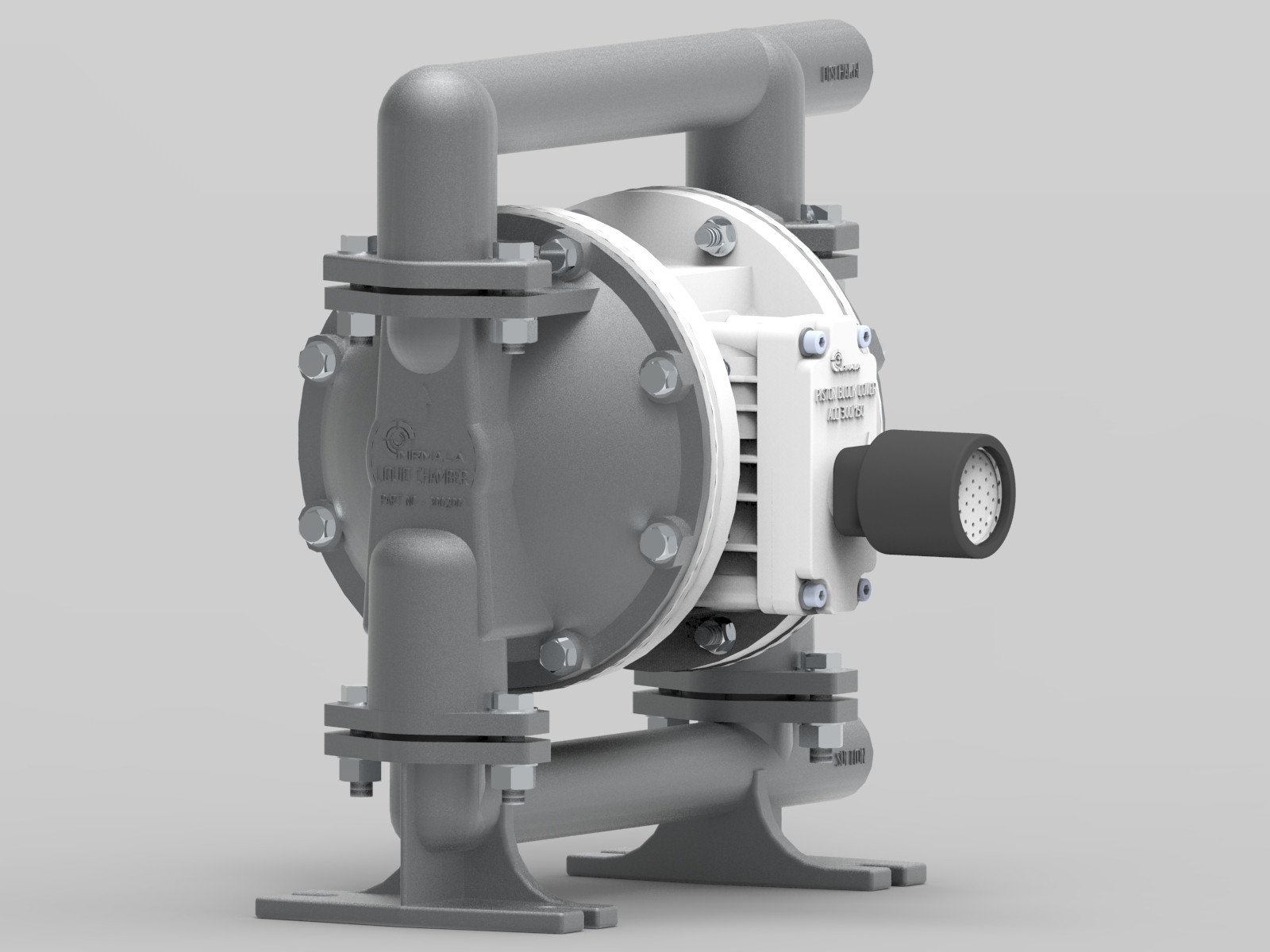

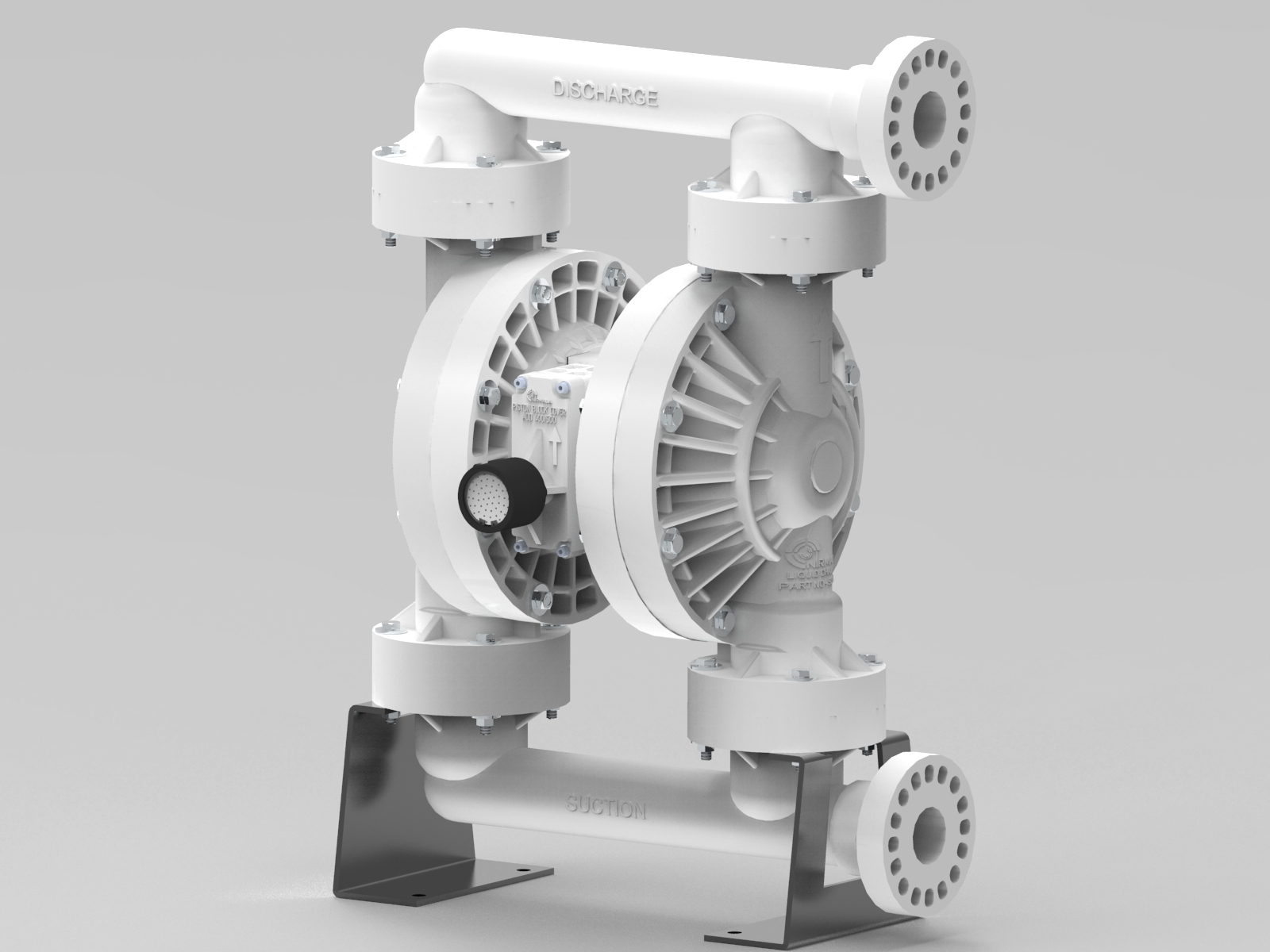

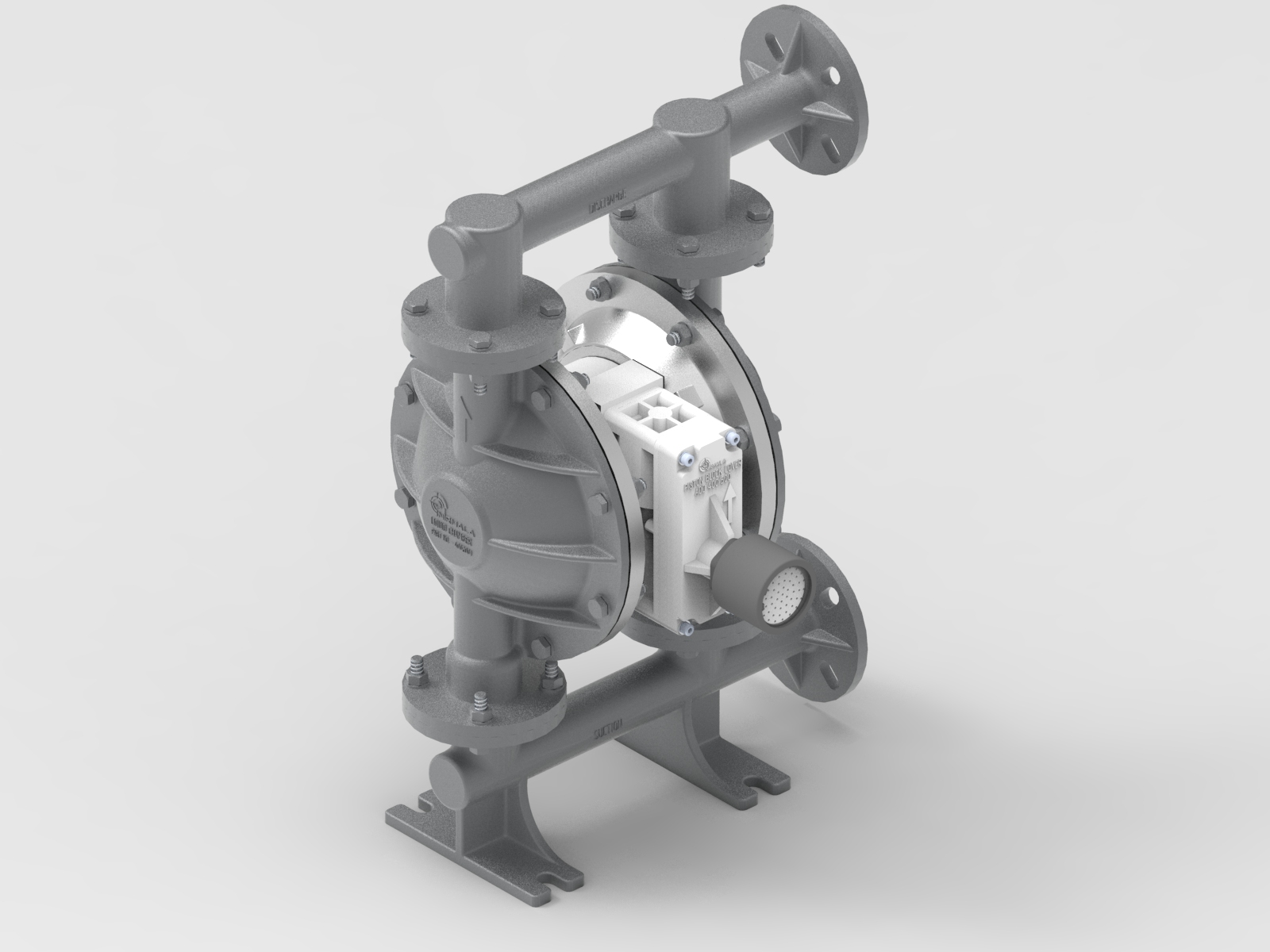

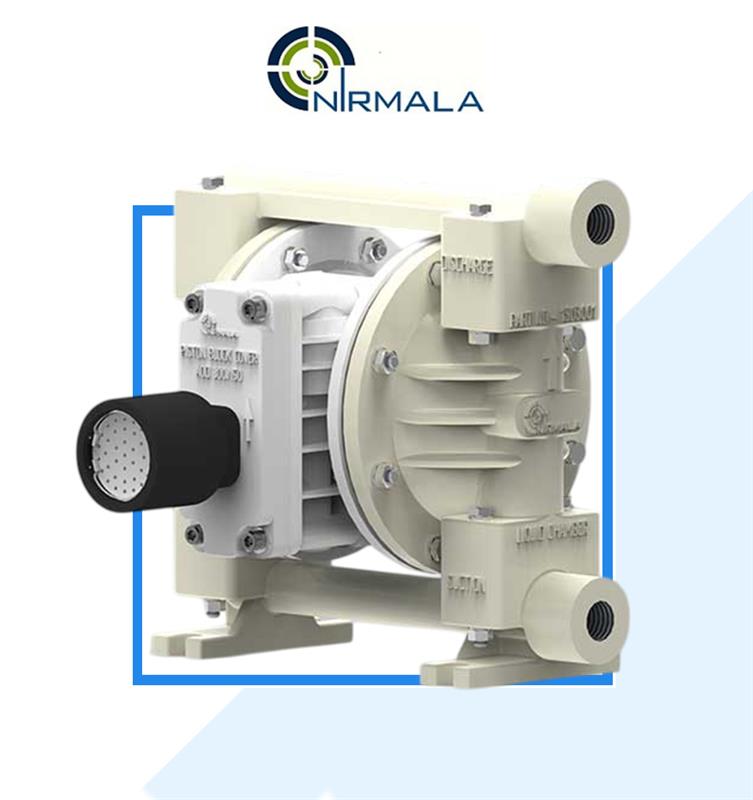

About Stainless Steel Diaphragm Pump

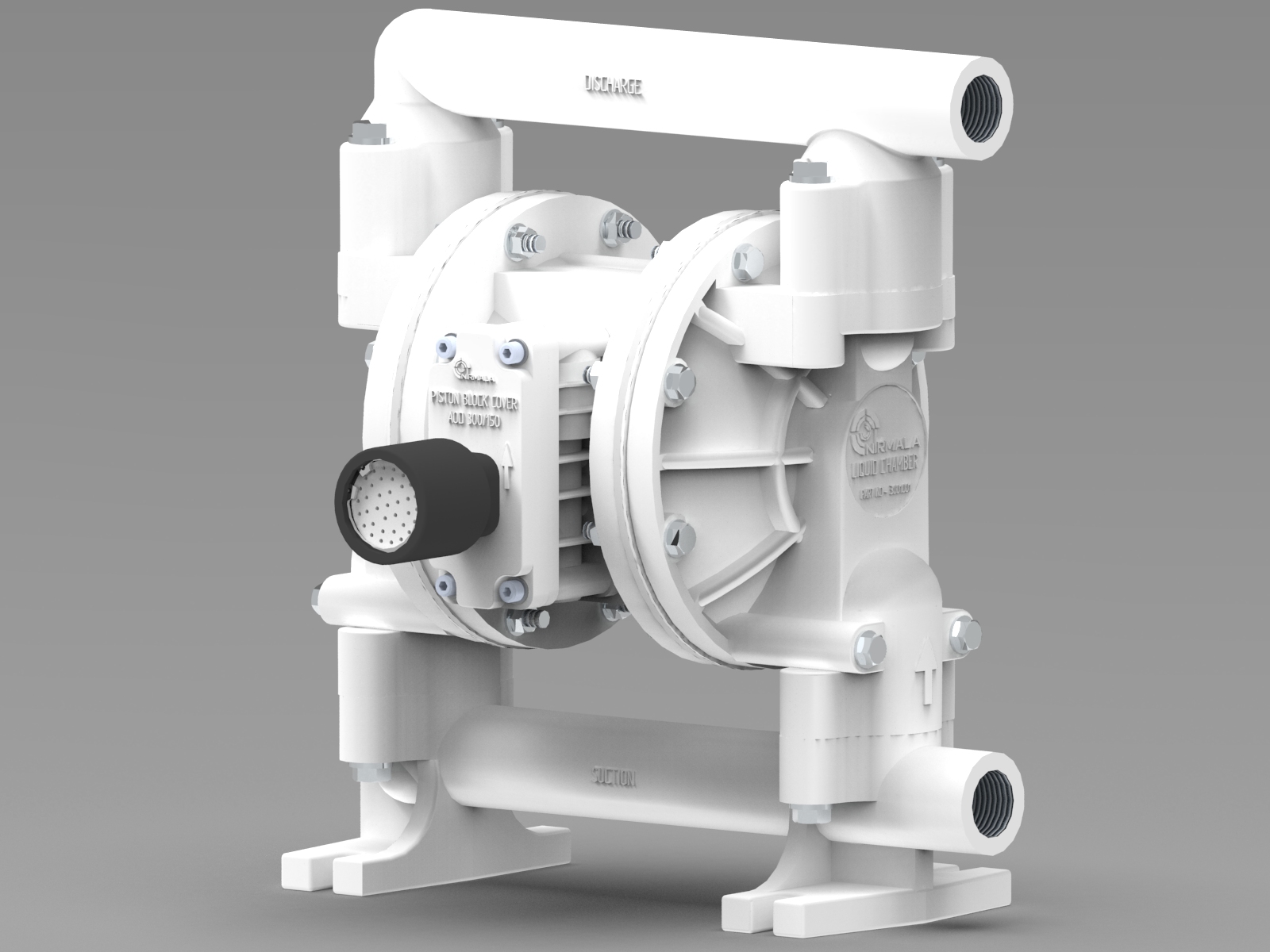

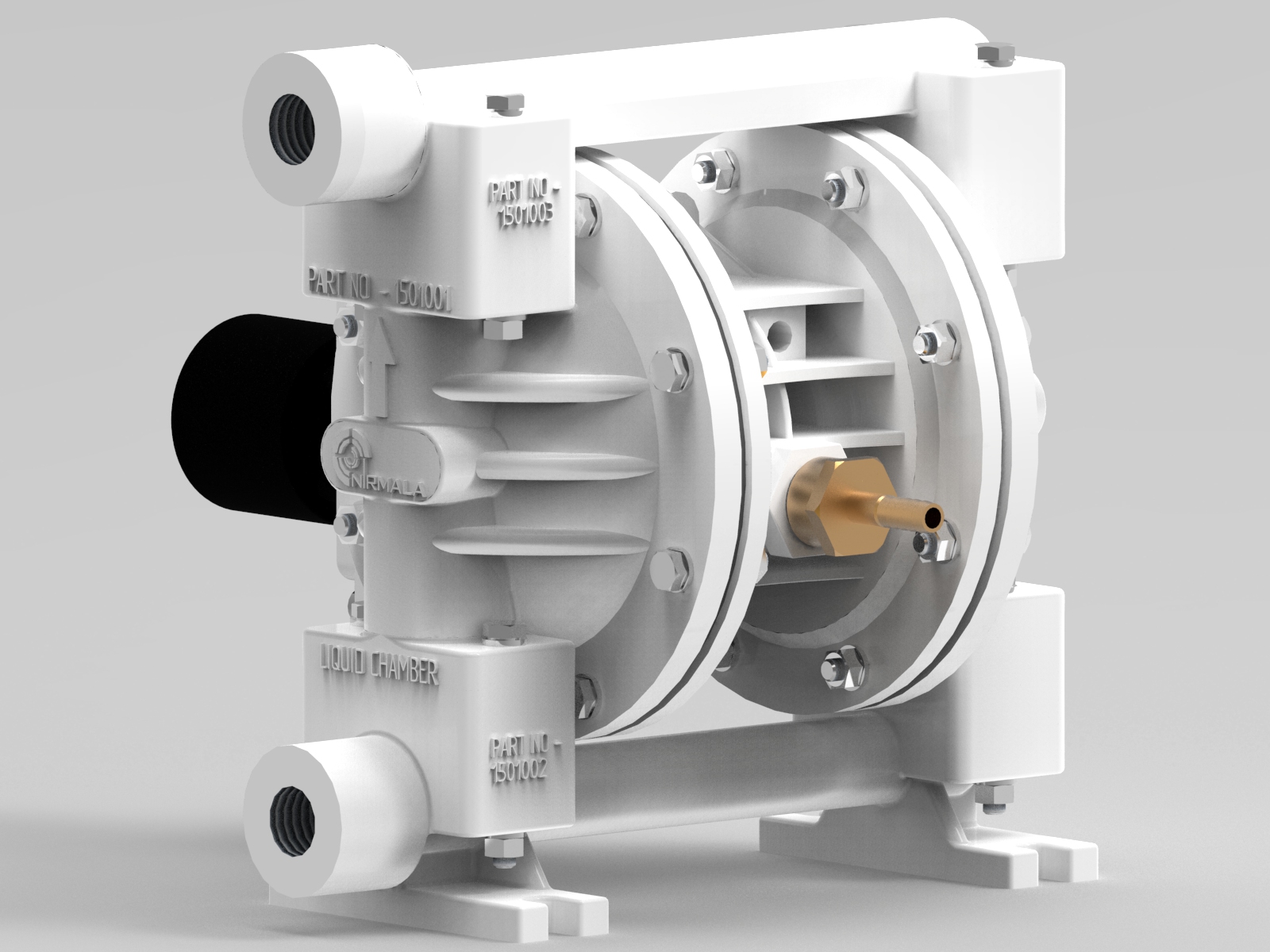

We are a leading Stainless Steel Diaphragm Pump manufacturer in India. These Metal series air-driven diaphragm pumps are known for their lightweight, smooth, and basic nature. These pumps have a SS housing and a PTFE diaphragm that can withstand a wide range of acids/alkalis/flammable liquids like phosphoric acid, acetone &methyl-ethyl-ketone.

They are intended for transporting vast amounts of heavy sludges&slurries and for dangerous/toxic/poisonous liquids in harsh conditions where the leakage is strictly prohibited.

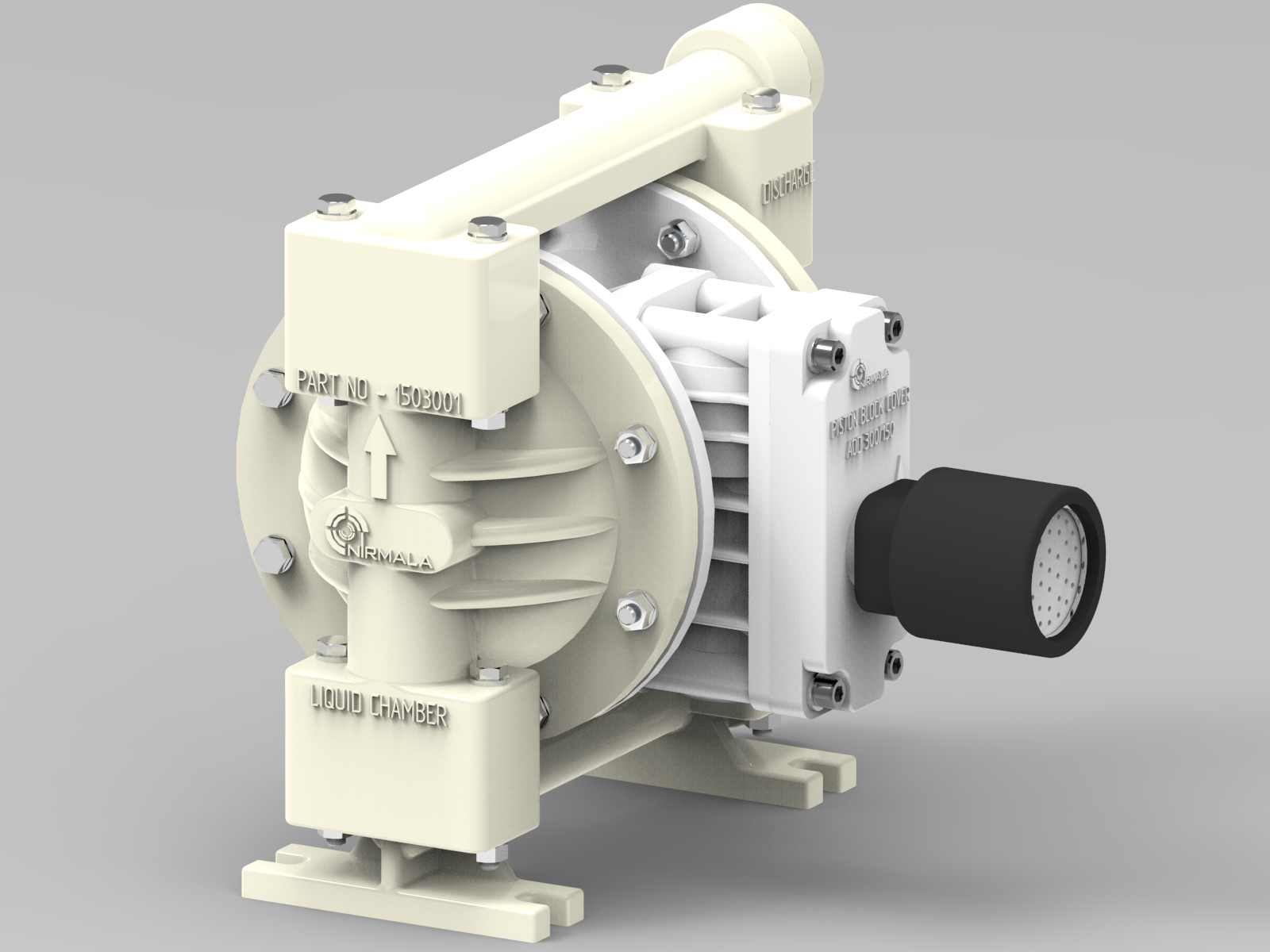

Pumps are self-priming, which ensures they generate suction to pull liquid upward into the pump cavity. Many of them are submersible and can be run dry. Furthermore, clients can avail of the offered Stainless Steel Diaphragm Pump from us at the most reasonable prices.

We are India’s best Stainless Steel Diaphragm Pump supplier, which is intended for general use. They can quickly move big particles from sterile, light viscosity fluids to corrosive, abrasive medium viscosity fluids.

Best Stainless Steel Diaphragm Pump

They may be used in highly explosive environments due to their pneumatic engine. The stainless steel diaphragm pump is constructed with precision components of the highest quality.

This product is cost-effective and lasts for a long time and when used in abrasive fluids. This pump is popular among professionals because it provides an easy, hands-off solution to their fluid handling needs. These pumps can adjust the flow outlet and discharge pressure using just an air filter/regulator and a needle valve, making them suitable for applications ranging from small volume dosing to high volume tank transfer and even filter press feeding.

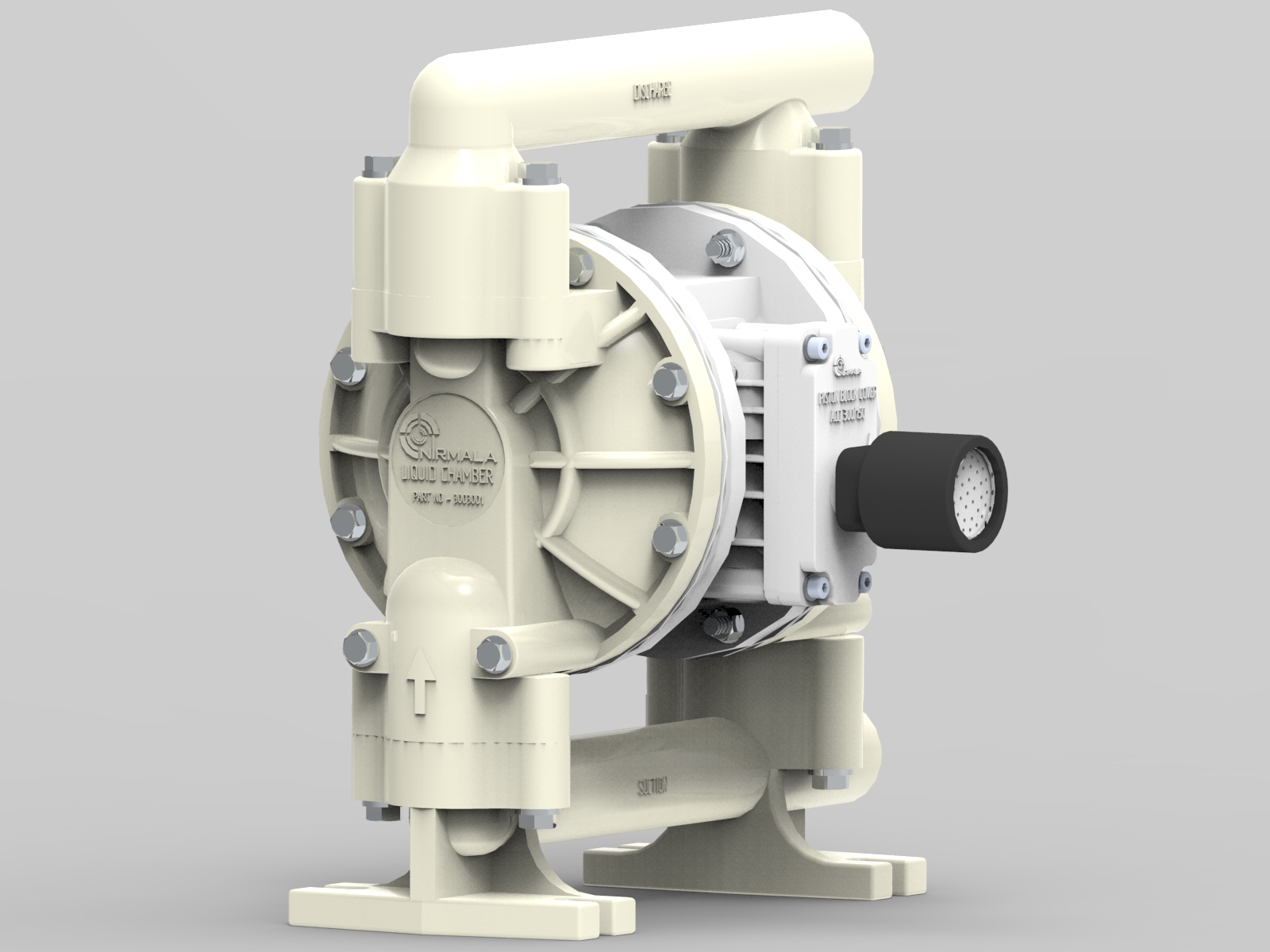

Features of Stainless Steel Diaphragm Pump

- Chemical/paint/adhesive stirring

- Pumping of hazardous waste/acids

- Used in dentistry instrumentation pumps

- Pneumatic Liquid Pumps: Used to transfer liquid

- Reduction in lost production, chemical waste, increased program effectiveness

- Pneumatic Refrigerant Pumps: Two-stage pumps are usually used to carry refrigerants.

- Reduced energy consumption, repair time, and other related reductions in operational costs.

- Pneumatic Test Pumps: It is designed and constructed to evaluate the efficacy of a specific pneumatic system.

- Oil and gas production applications/pulp&paper/fertilizer dosing/water treatment/food processing industries.

- Pneumatic Diaphragm Pumps: It makes use of a plunger and piston system to transfer media into a cylindrical chamber. A pneumatic, electric, hydraulic, or steam drive powers this mechanism.